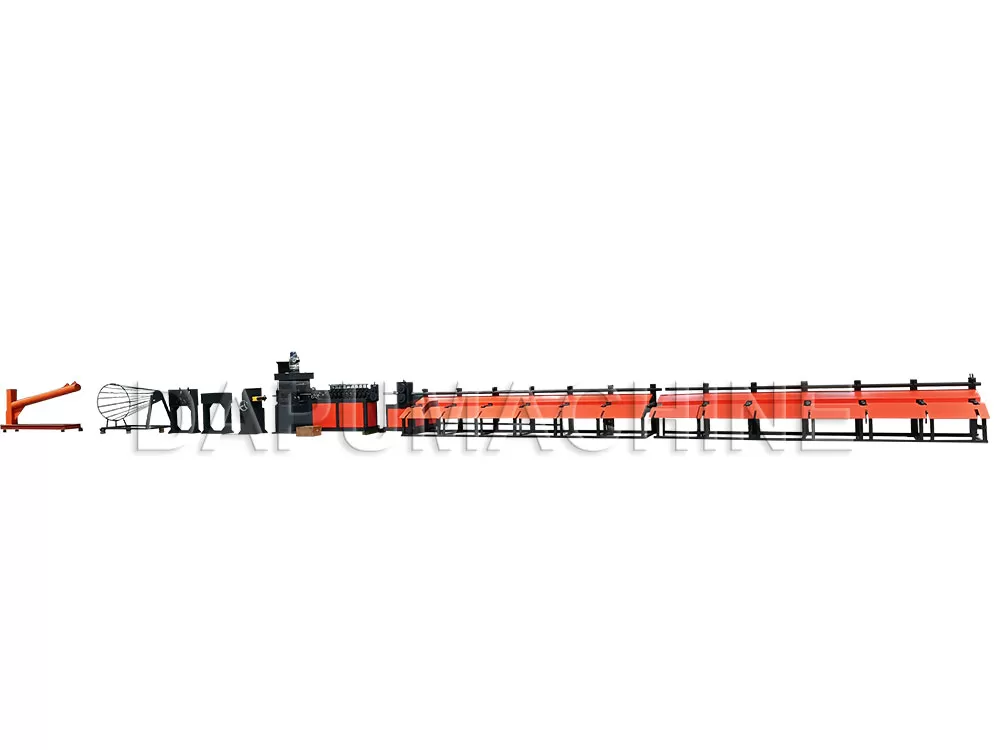

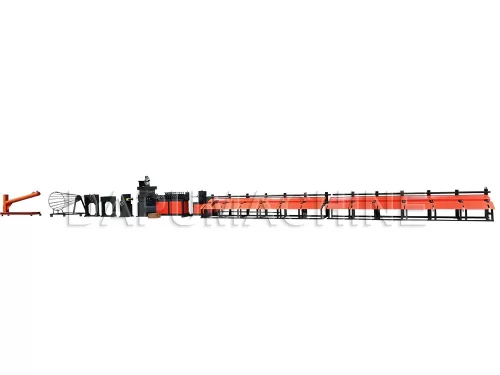

2 ribs cold rolling steel rebar ribbed machine

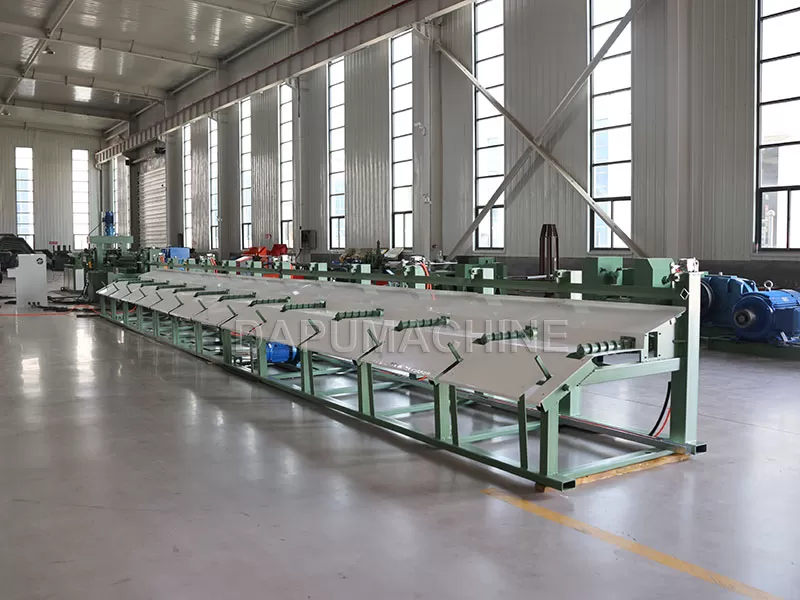

The 2 Ribs Cold Rolling Steel Rebar Ribbed Machine efficiently produces wire coils and straight wires. The process includes a wire guide bracket, mechanical descaler, lubrication system, pay mill, and main rolling mill for effective ribbing. It features inverter control for adjustable speed, ensuring smooth and efficient operation.

Privacy Policy:

Samples are free within a certain price range

Description & Video

1.Output wire type: wire coils, straight wires.

2.Process: Raw material–Wire guide bracket–Mechanical descaler–Lubrication part–Pay mill—Main rolling mill—straightening&cutting/coiling

3.Inverter control speed.

4.The machine color supports customization.

Technical Parameter

| Model | LZ-50000T |

| Max.inlet wire diameter | Φ6-14mm |

| Finished ribbed diameter | Φ5-13mm |

| Max.rolling speed | 150-180m/min |

| Wire coil weight | 1T/2T/3T option |

| Max.straightening&cutting speed | 120m/min |

| Cutting length | 1-12m |

| Speed adjusting way | Frequency inverter |

| Control system | PLC+touch screen |

| Cut off error | ±5mm |

| Cutting way | Servo flying cutting |

| Rolling motor | 110kw |

| Cutting motor | 22kw (Servo flying cutting) |